Rhenium Scrap Recycling

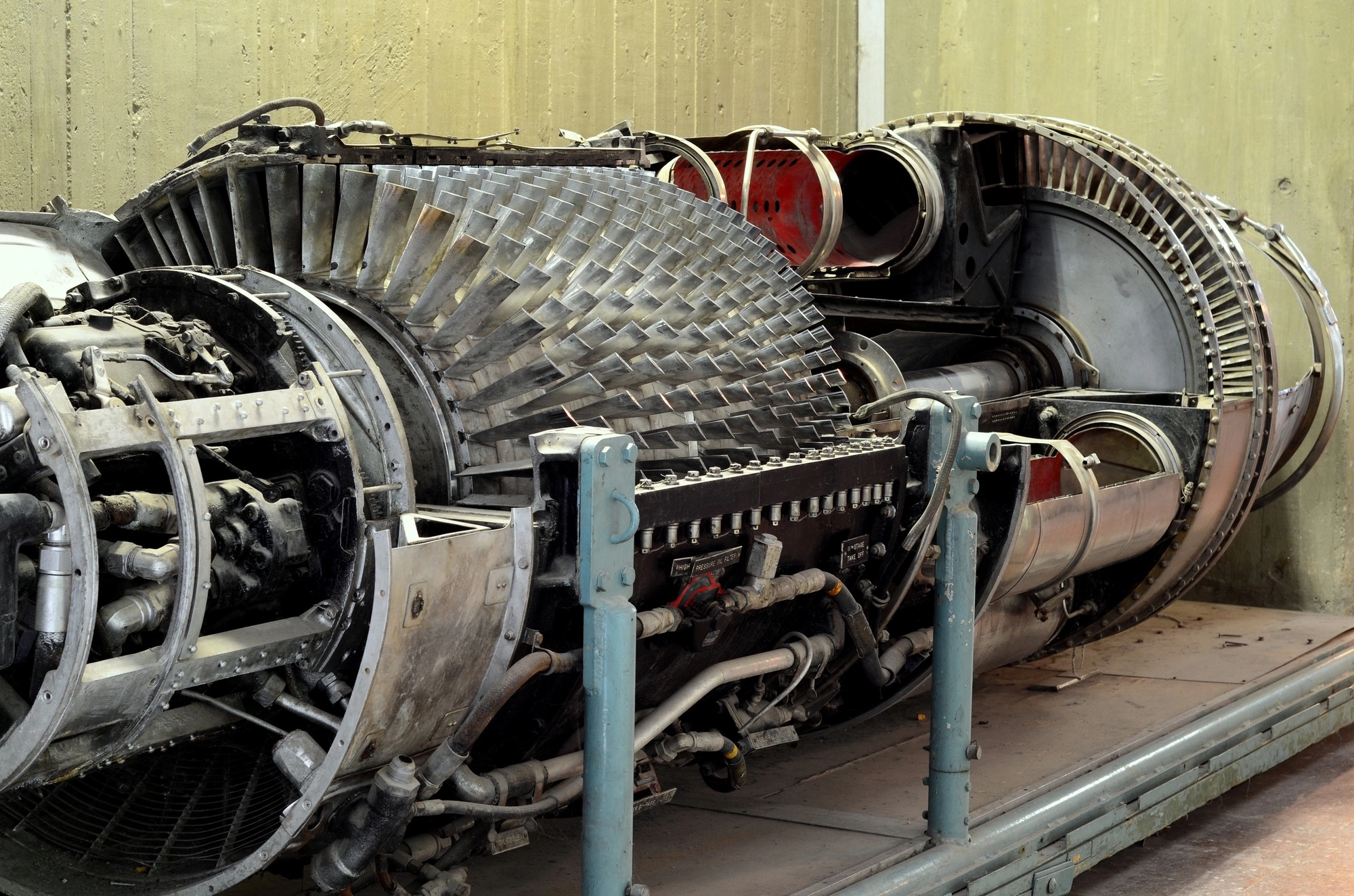

Quest Alloys specializes in rhenium scrap recycling and purchases all forms of rhenium-bearing material, including superalloy turbine blades and refinery units.

Quest Alloys specializes in rhenium scrap recycling and purchases all forms of rhenium-bearing material, including superalloy turbine blades and refinery units.

Rhenium is one of the most rare and finite elements in Earth’s crust. As such, it’s exceedingly important to salvage rhenium-bearing scrap. Our global team will travel to any location in the world to inspect, sample and verify rhenium materials. Furthermore, we offer top rhenium price for your scrap, and pride ourselves on fast service, payment and delivery of goods to our global consumers.

As an ISO 9001 certified processor and supplier, we are compliant with all major air and vacuum smelters. But what truly sets us apart is our capacity to handle all logistics related to the import and export of your metals and alloys.

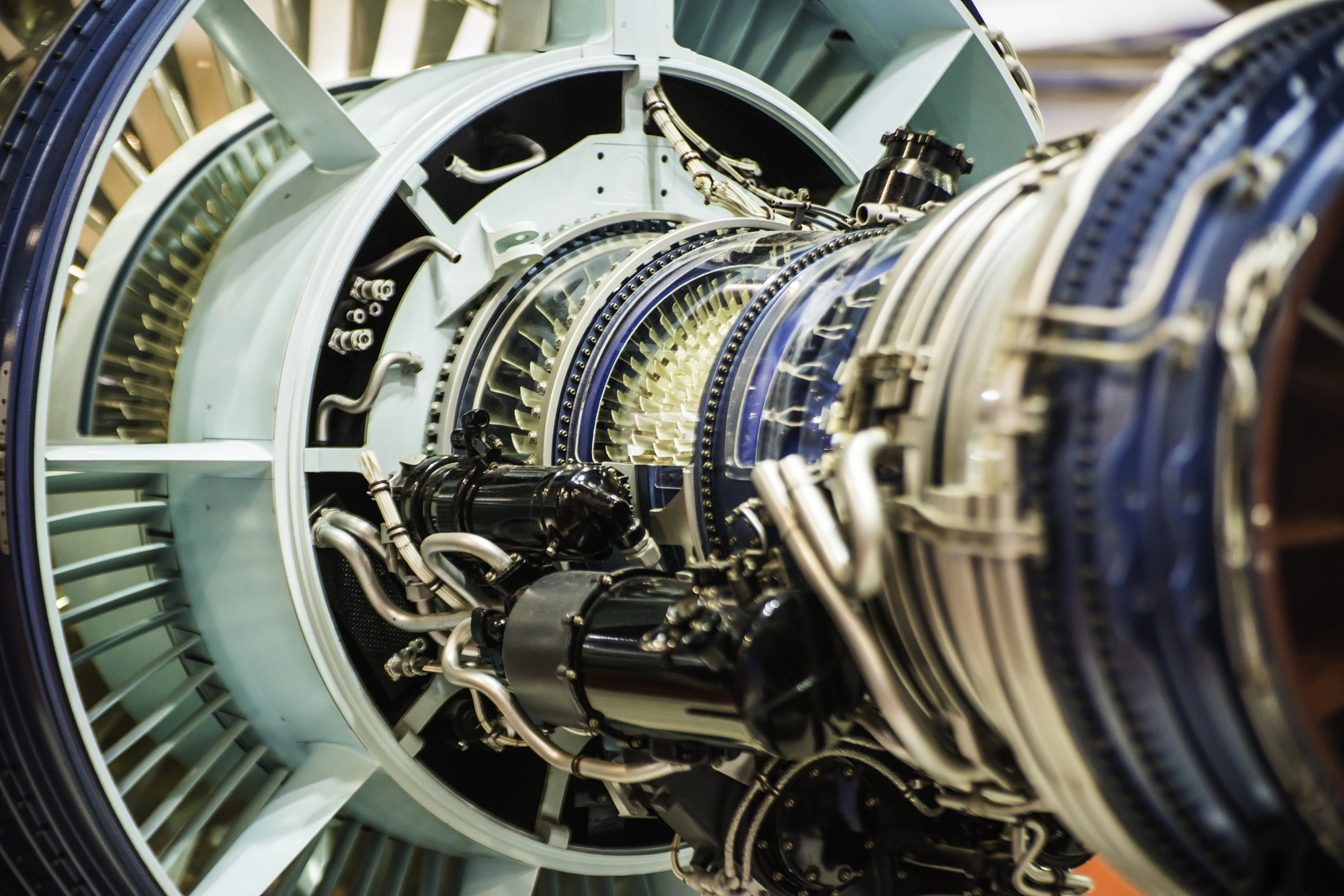

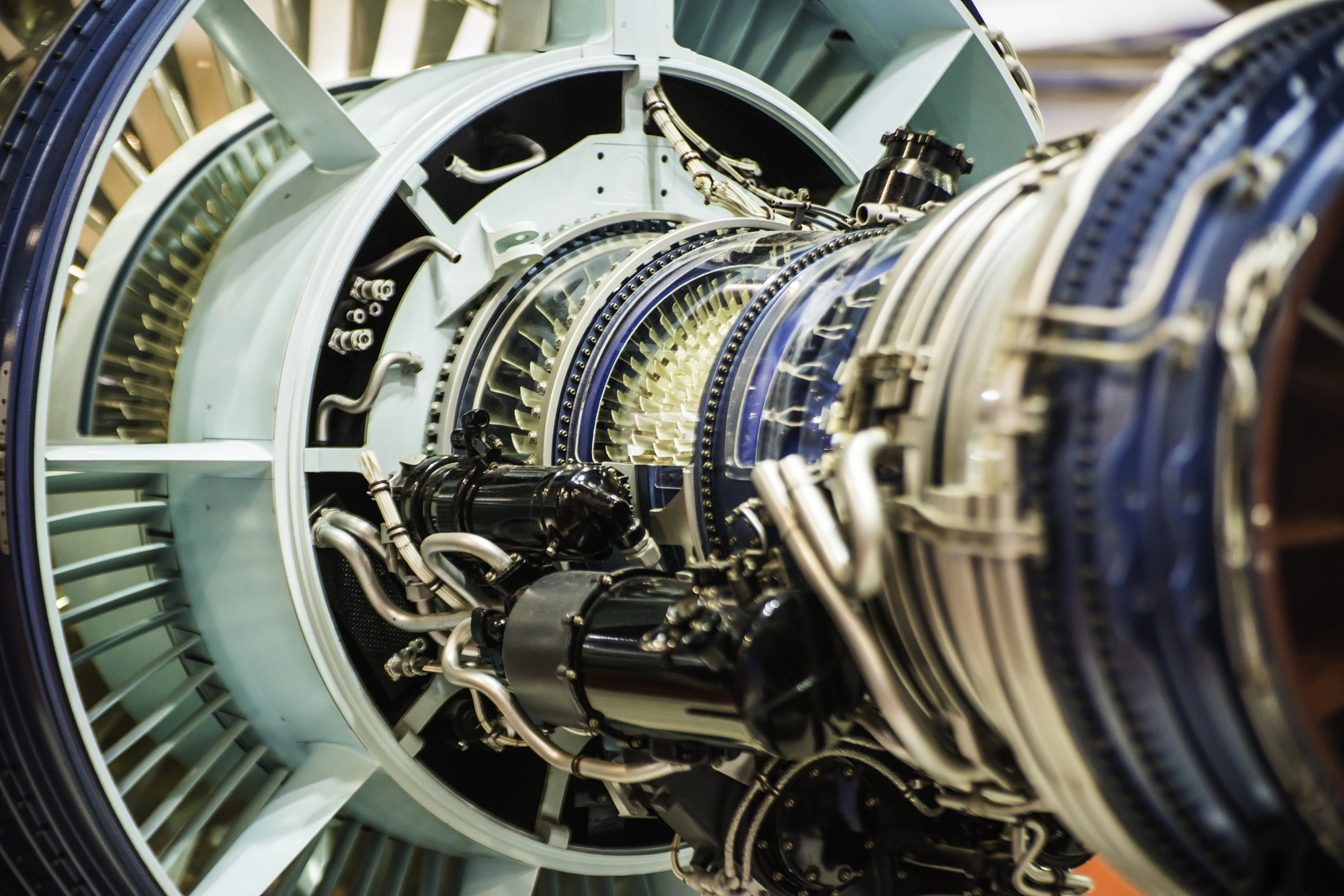

Rhenium has one of the highest melting points of all the elements. It’s also an incredibly dense metal. Almost three-quarters of all the earth’s rhenium is used in the manufacturing of superalloys for jet engine and military or civil engine parts, including: turbine blades, vanes, and combustion liners. Containing 2 to 6 percent rhenium, superalloys have the ability to tolerate high temperatures and exposure to high oxygen levels.

Second to jet engine manufacturing is rhenium’s usage in platinum-rhenium catalysts, which are mainly used to make lead-free, high-octane gasoline. A catalyst is a substance used to speed up or slow down chemical reactions without changing itself. Other rhenium uses include devices that control temperature, like thermostats, heating elements, vacuum tubes, etc.

Through Rhenium scrap recycling efforts, 10 tons of rhenium are salvaged annually, and because the metal is so rare, Rhenium price remains stable or rising.