The aircraft manufacturing industry has increasingly turned its attention to the end-of-life (EOL) phase of aircraft as a critical component of sustainability. The largest manufacturers, Airbus and Boeing, have made significant strides in developing environmentally responsible practices for aircraft decommissioning, recycling, and material recovery. These efforts not only help reduce environmental impact but also contribute to the industry's broader green initiatives.

Airbus has been a pioneer in addressing the environmental impact of aircraft at the end of their service life. Recognizing the growing need for sustainable practices, Airbus launched the PAMELA (Process for Advanced Management of End-of-Life Aircraft) project in 2005 in collaboration with Suez-Sita, a French recycling company, and the European Union. The project aimed to demonstrate that up to 85-95% of an aircraft could be recycled, reused, or recovered. Additionally, it sought to create a new standard for the safe and environmentally friendly management of End-of-Life Aircraft (ELA) while launching a European network to support the dismantling process.

The project’s early success was highlighted by the dismantling of an Airbus A300-B2 at Tarbes Airport in 2006, marking the world’s first full-scale aircraft decommissioning demonstration. The A300 was decommissioned and dismantled, with data gathered on the effectiveness of the methods used. By 2007, the project had demonstrated that 85% of the aircraft's weight could be valorized, and 90% of the energy and mining resources associated with its metallic materials were saved.

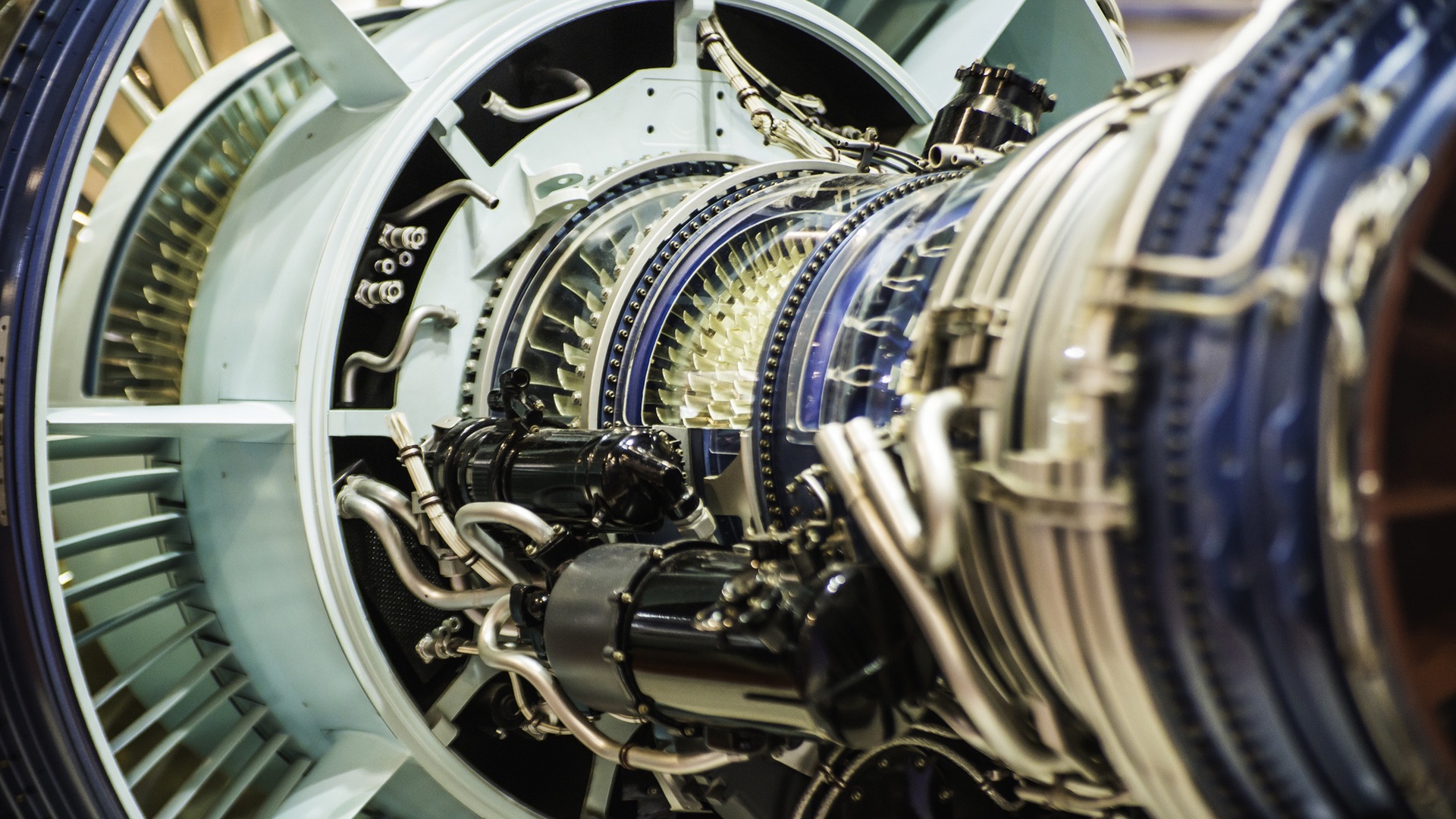

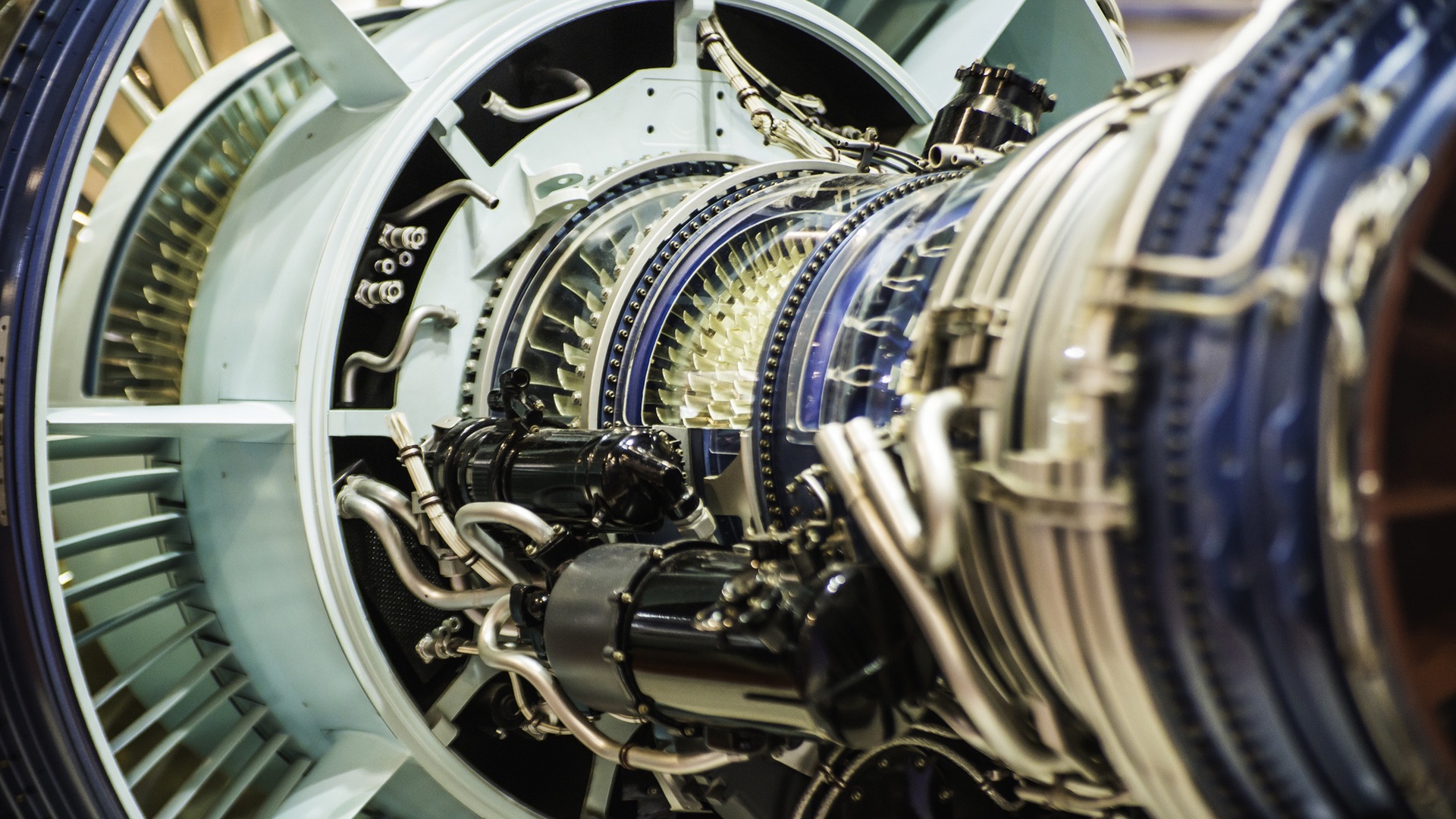

Following the success of PAMELA, Airbus expanded its efforts with the PAMELA A380 project in 2007, using an A380 static test frame to assess the recovery potential of materials and alloys used in larger aircraft. This project achieved an impressive 98% recovery rate for metallic components, setting a new benchmark in the industry. Airbus also pioneered the concept of “smart disassembly”, which not only focused on the technical aspects of recycling but also considered the economic implications of dismantling and recycling larger aircraft.

The success of these projects led to the creation of Tarmac Aerosave, a joint venture between Airbus, Snecma Services, and Aeroconseil, focused on the environmentally responsible recycling, storage, and maintenance of aircraft. Tarmac Aerosave’s first dismantling facility opened in 2009 in Tarbes, France, and by 2020, it had recycled 170 aircraft and 135 engines, with a recycling rate exceeding 90%. The company’s expansion included new facilities in Teruel, Spain, and Toulouse Francazal, France, further demonstrating Airbus’ commitment to sustainability and responsible aircraft end-of-life management.

While Airbus took early strides in aircraft recycling, Boeing faced unique challenges due to the relative age of its fleet. The Boeing 707, which first flew in 1957, represents a significantly older fleet compared to Airbus’ newer models, thus contributing to a higher number of aircraft being retired from service. To address this challenge, Boeing adopted a different approach by founding the Aircraft Fleet Recycling Association (AFRA) in 2006 in collaboration with ten European and American companies. These companies, representing industries such as aircraft maintenance, manufacturing, waste management, and commodity production, formed a self-financing non-profit organization aimed at improving the standards and processes for aircraft end-of-life management.

AFRA’s mission is to create a global network of organizations across the entire aircraft lifecycle, from manufacturers to material recyclers, fostering collaboration and sharing best practices for dismantling and recycling. The association developed a series of Best Management Practice (BMP) guides, with the most recent version (4.0) released in 2019. These guides provide clear recommendations for managing parts removed from aircraft during disassembly and the recycling of those materials in a way that ensures safety, environmental responsibility, and compliance with legislation.

Boeing, as a member of AFRA, along with other major companies like Tarmac Aerosave, Embraer, Lufthansa Technik, and Pratt & Whitney, has played a crucial role in shaping the aircraft recycling industry. According to Perry (2012), AFRA members are responsible for dismantling and parting out approximately one-third of the aircraft scrapped worldwide, underscoring the association’s significant impact on the recycling culture within aviation. Boeing’s participation in AFRA has enabled the company to stay at the forefront of aircraft end-of-life management, benefiting from the collective knowledge of the global network of stakeholders.

Both Airbus and Boeing have demonstrated leadership in aircraft recycling through their respective initiatives. Airbus’ PAMELA project has set benchmarks for the recycling of aircraft, and its collaboration with Tarmac Aerosave has resulted in a practical, operational model for large-scale aircraft dismantling. Meanwhile, Boeing's involvement in AFRA has created a global network of stakeholders that has significantly advanced recycling practices across the industry.

In addition to their efforts at the corporate level, both companies are actively working with aviation authorities like the FAA and EASA to gain official recognition of their best practices. AFRA’s efforts to get the BMP guides accredited by these authorities would pave the way for a more standardized and regulated approach to aircraft end-of-life management.

The ongoing efforts of both Airbus and Boeing highlight the increasing importance of sustainability in aviation, particularly as the industry works toward reducing its environmental footprint. By focusing on recycling, material recovery, and responsible disposal, both manufacturers are making significant strides toward a greener future for aviation.

Maaß, S. (2020). Aircraft Recycling–A Literature Review.