Gallium is an intriguing metal with unique properties that have sparked interest in various industries, including aviation and energy. While gallium is commonly known for its low melting point, making it a liquid at just above room temperature, its interactions with other metals, especially aluminum, raise questions about its potential to "melt" or destroy them.

In this article, we will explore the effects of gallium on different metals, focusing on a critical industrial concern: Does gallium melt metal? This comprehensive guide also touches on the gallium aluminum reaction, gallium's impact on steel, and its broader implications for industries reliant on metal durability.

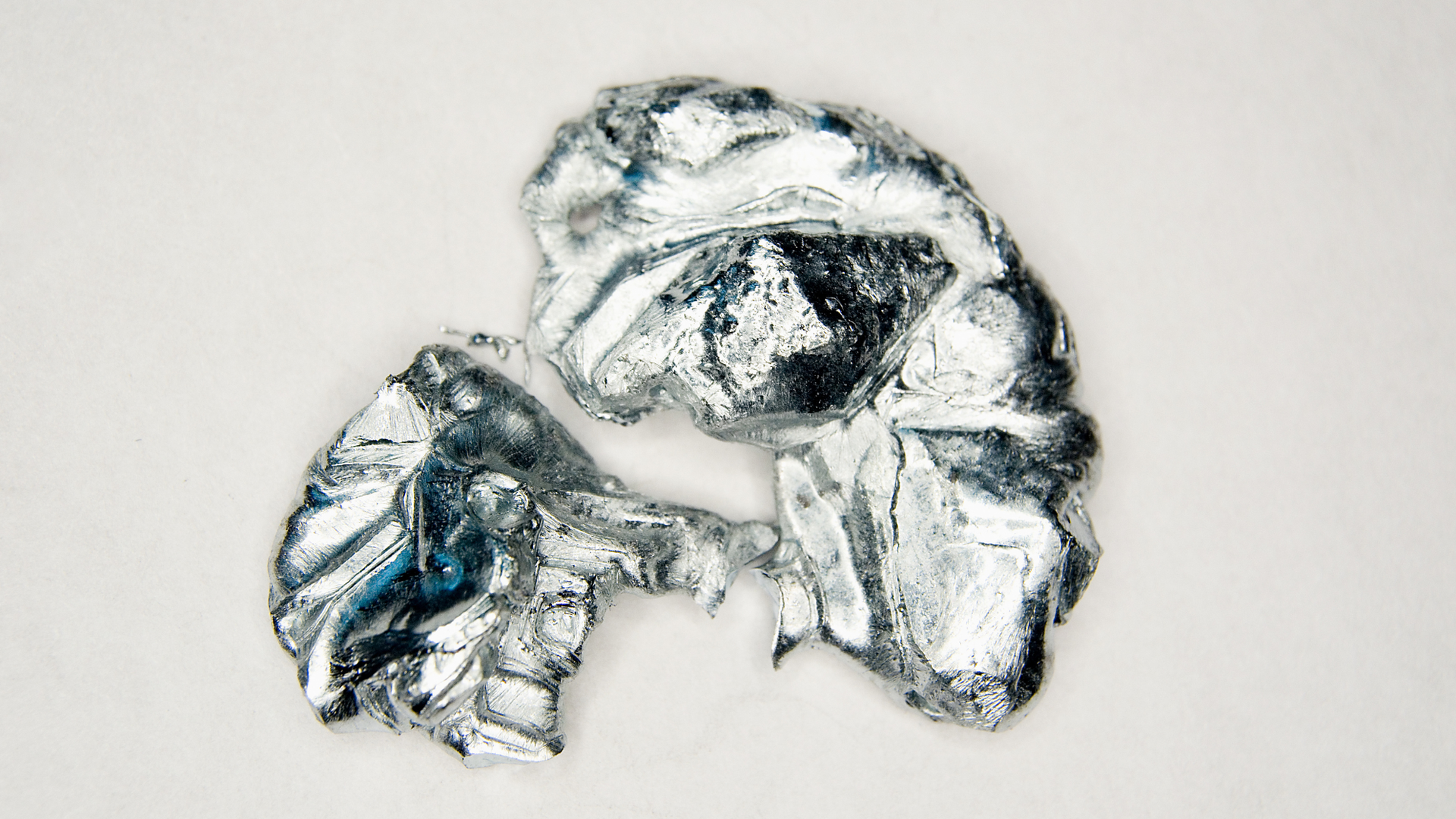

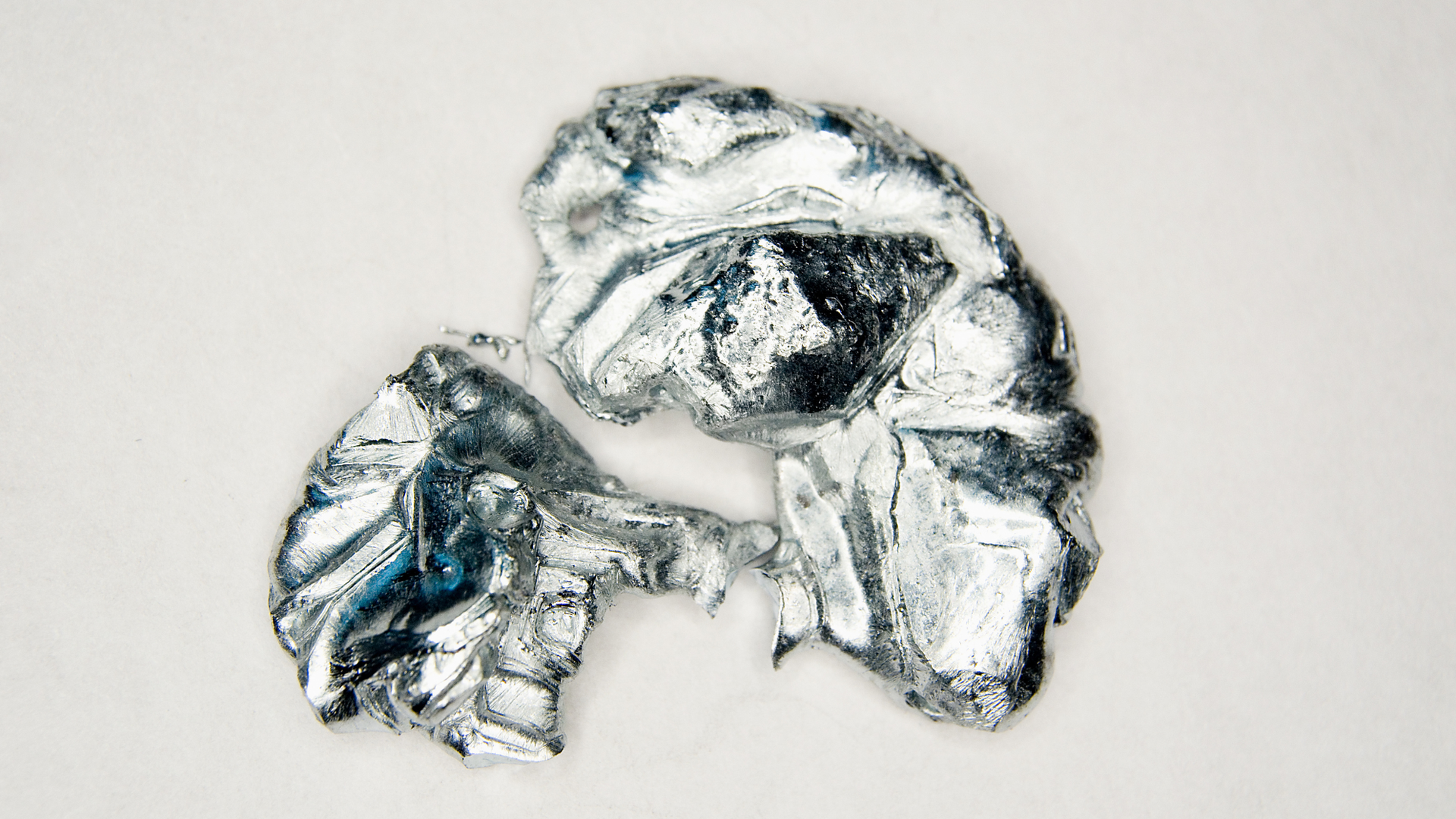

The reaction between gallium and aluminum is well-documented. When gallium is applied to aluminum, it doesn’t form a chemical bond but rather acts as a disruptive agent at the atomic level. Aluminum is known for its protective oxide layer, which prevents corrosion. However, when gallium comes into contact with this layer, it penetrates the protective oxide layer that naturally forms on aluminum, preventing it from reforming and leaving it vulnerable to corrosion. This exposure is further exacerbated by a phenomenon known as liquid metal embrittlement, where gallium infiltrates the grain boundaries of the metal, making it extremely brittle and prone to cracking under stress. Together, these processes significantly compromise the durability and integrity of aluminum.

As gallium infiltrates aluminum’s grain boundaries, it prevents the metal atoms from holding together in a cohesive lattice. This causes the aluminum to become brittle and eventually crumble. This weakening effect can pose serious risks for industries that rely on aluminum for its strength-to-weight ratio, like aviation and automotive manufacturing.

Unlike aluminum, steel does not exhibit the same vulnerability to gallium. Gallium’s impact on steel is minimal because steel has a much more complex atomic structure and is less reactive. While gallium may interact with steel’s surface, it does not penetrate or cause the same level of degradation seen in aluminum.

That said, gallium on steel can still pose minor concerns for specific applications. Prolonged exposure of steel to gallium might lead to some surface corrosion or weakening, but it is not as significant or immediate as the gallium-aluminum reaction.

Industries that use steel in high-stress environments, such as energy and heavy machinery, can generally consider steel safe from gallium’s more destructive properties. However, care should still be taken to avoid unnecessary exposure, particularly in environments where a mix of metals might be used.

The term “destroy” can be misleading when describing gallium’s effects on metals. Gallium doesn’t chemically react with metals in the way that acids or other corrosive substances do. Instead, it disrupts the metal's internal structure, specifically in aluminum, leading to weakening and crumbling.

This phenomenon is often referred to as "liquid metal embrittlement”, where a metal loses its ductility and strength when a liquid metal like galium infiltrates the grain structures of metals like aluminum becoming brittle and prone to failure. Gallium’s ability to cause embrittlement is what leads people to say it “destroys” metals like aluminum. In contrast, gallium’s effects on metals like steel and titanium are far less pronounced.

Gallium itself is not classified as a corrosive material. However, its ability to disrupt metal structures, particularly aluminum, can have effects that mimic corrosion. Gallium’s behavior at the atomic level causes embrittlement and weakening, which is why it can be perceived as a corrosive agent when applied to metals like aluminum.

For industries dealing with metal recycling or the handling of gallium metal, understanding these properties is critical for maintaining the integrity of materials. Ensuring proper precautions are in place when working with gallium can prevent structural failures in metal components.

Gallium is a highly versatile element used across various industries in different chemical forms:

Gallium Nitrate (Ga(NO₃)₃), produced from 4N purity gallium, is utilized in pharmaceuticals to treat conditions like navicular syndrome in horses and hypercalcemia in humans, while also serving as a catalyst in petrochemical processes.

Gallium Trichloride (GaCl₃), made from 4-5N purity gallium, is key in producing organometallic compounds and improving battery efficiency.

Gallium Trioxide (Ga₂O₃) plays an essential role in manufacturing langasite crystals for communication technologies and phosphors for LED production. Triethylgallium (TEGa) and Trimethylgallium (TMGa) are critical in the growth of epitaxial layers for LED production, with TMGa being the most widely used.

Gallium Nitride (GaN) is fundamental to military radar, aerospace, LED, and wireless applications due to its superior power density and durability, although its bulk production remains challenging.

Other significant gallium compounds include Gallium Phosphide (GaP), used in visible-spectrum LEDs, and Gallium Arsenide (GaAs), which is highly efficient in cell phones, military systems, and wireless communications due to its speed and temperature resistance. Gallium also contributes to photovoltaic applications, particularly in extraterrestrial solar cells, and is combined in eutectic alloys for various electronic devices.

Gallium Antimonide (GaSb) is vital for infrared systems, while GaAs semiconductors are pivotal in amplifying signals and enabling high-speed data transmission in telecommunications and military technologies. With its unique properties, gallium remains indispensable in sectors requiring high efficiency, durability, and advanced performance.

As demand for advanced materials grows, industries will increasingly need efficient solutions for managing gallium scrap and recyclable metals. Quest Metal offers recycling services that help companies safely handle and process gallium and other metals. By partnering with us, you can ensure your materials are responsibly recycled, protecting your assets and the environment.

Contact Quest Metal today to sell your recyclable metals and explore sustainable recycling solutions for gallium and other valuable materials.