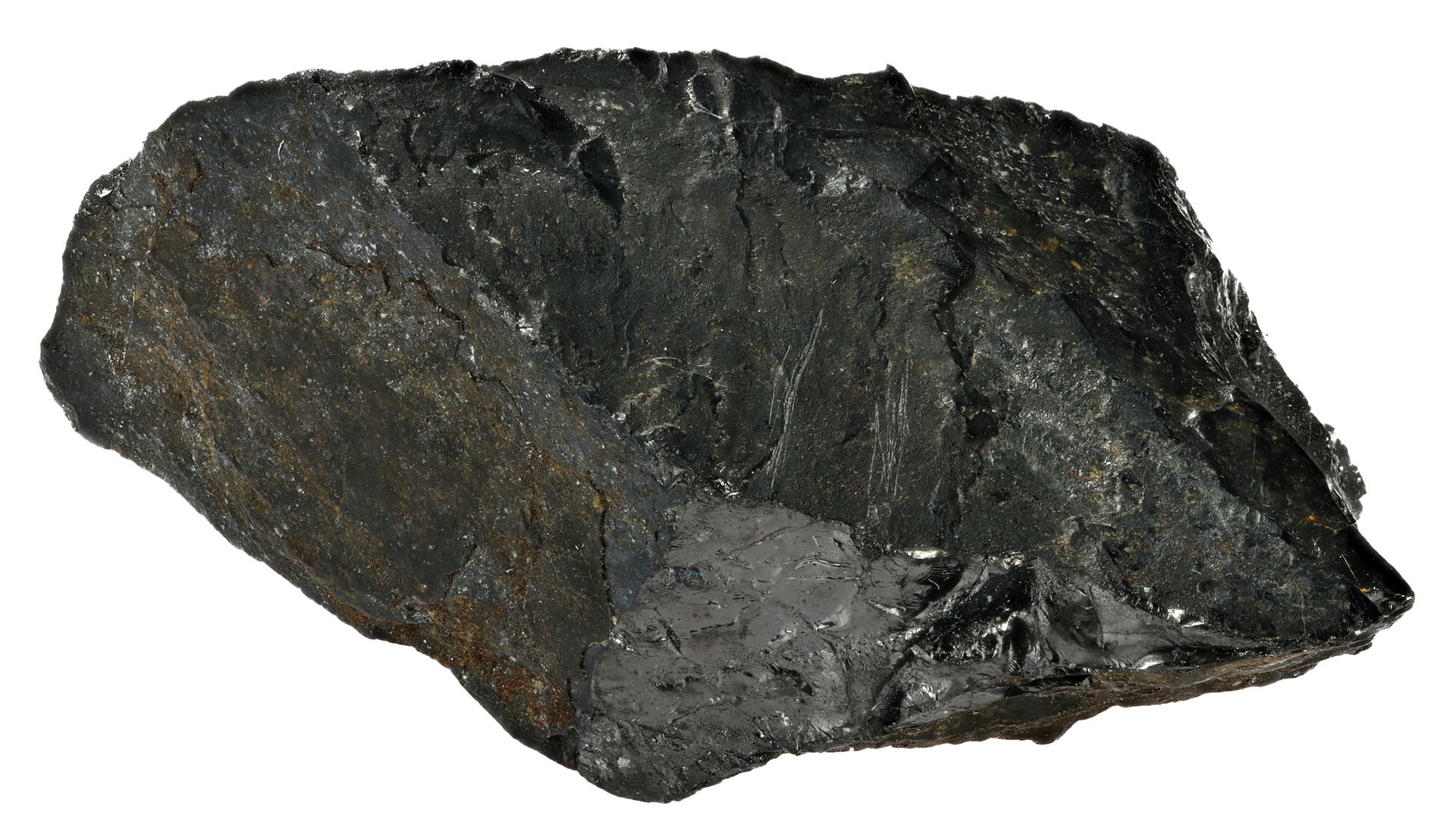

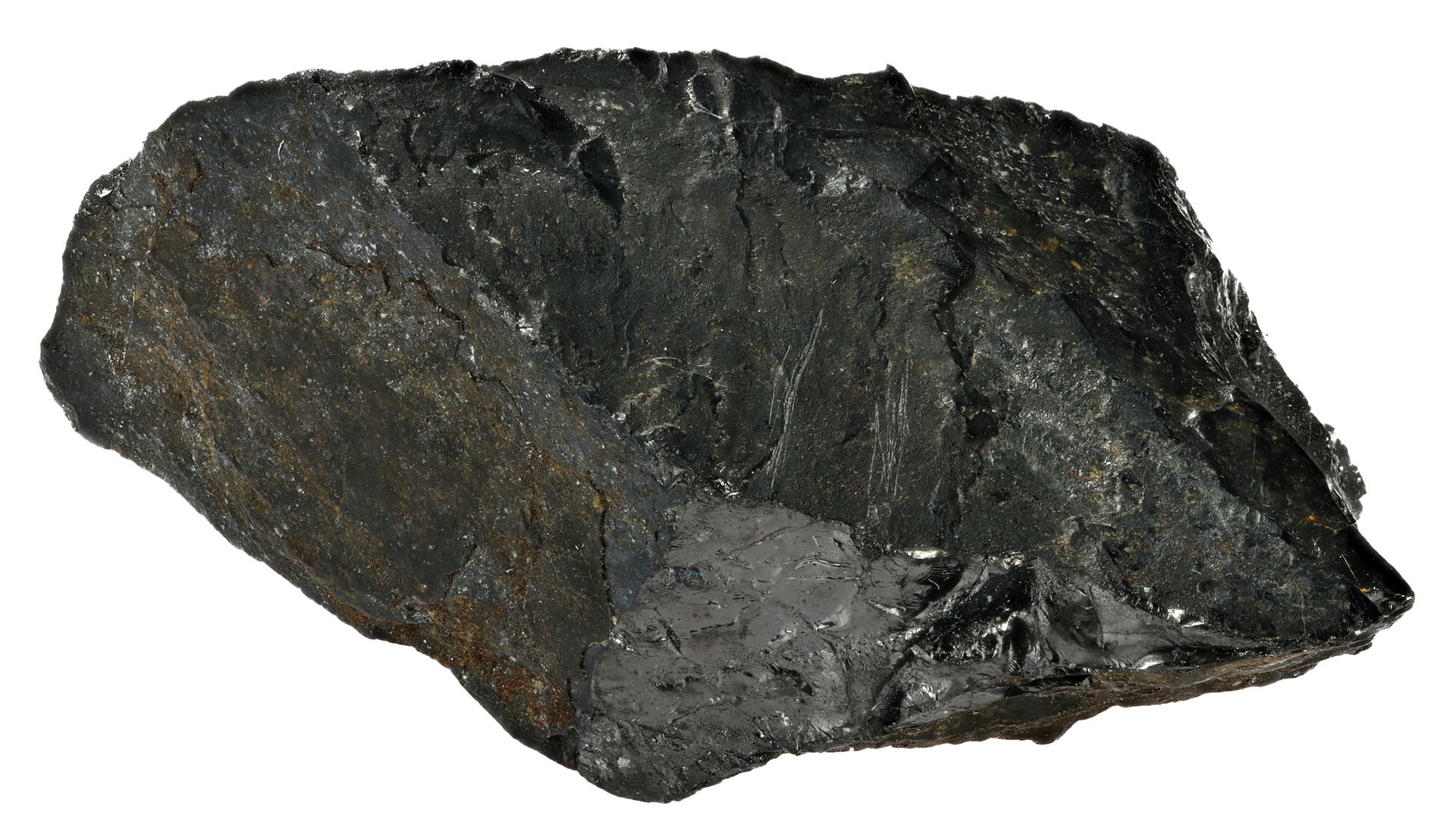

Titanium is a remarkable metal renowned for its exceptional strength-to-weight ratio, corrosion resistance, and versatility. These properties make it a preferred choice across various industries, including aerospace, medical, and automotive. However, the wide array of titanium alloys and grades can be overwhelming. This blog provides a detailed overview of titanium grading, types, and their applications to help you make informed decisions for your projects.

Titanium alloys are broadly classified based on their microstructure and strength characteristics. Understanding these classifications helps in selecting the right alloy for specific applications.

Titanium alloys can be categorized into three main groups based on their predominant phase or phases:

Titanium alloys are also classified based on their strength characteristics:

The physical and mechanical properties of titanium alloys can be tailored by adding various alloying elements:

The diverse properties of titanium alloys make them suitable for a range of applications:

To provide a clearer understanding of the different titanium grades and their applications, here's a table summarizing the key information about titanium alloys:

Alloy (ASTM Grade) |

Composition |

Description |

Typical Forms |

Applications |

Commercially Pure Grades | ||||

Ti Grade 1 |

Unalloyed Titanium |

Lowest strength, highest ductility, excellent corrosion resistance |

Ingot, Bar, Billet, Plate, Sheet, Wire, Tubing |

Chemical processing, desalination, medical, marine |

Ti Grade 2 |

Unalloyed Titanium |

Moderate strength, good corrosion resistance, weldable |

Ingot, Bar, Billet, Plate, Sheet, Wire, Tubing |

Chemical processing, marine, oil & gas, desalination |

Ti Grade 3 |

Unalloyed Titanium |

Higher strength than Gr. 2, good corrosion resistance |

Ingot, Bar, Billet, Plate, Sheet, Wire, Tubing |

Chemical processing, marine, aerospace |

Ti Grade 4 |

Unalloyed Titanium |

Strongest unalloyed titanium, moderate formability, excellent corrosion resistance |

Ingot, Bar, Billet, Plate, Sheet, Wire, Tubing |

Aerospace, chemical processing, marine, medical |

Commercially Pure Grades Modified with Pd or Ru | ||||

Ti-0.15Pd (Grade 7) |

Ti with 0.15% Pd |

Excellent resistance to reducing acids and chlorides, equivalent to Gr. 2 |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, desalination, marine, offshore |

Ti-0.15Pd (Grade 11) |

Ti with 0.15% Pd |

Soft grade with enhanced corrosion resistance, equivalent to Gr. 1 |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, desalination, marine, medical |

Ti-0.05Pd (Grade 16) |

Ti with 0.05% Pd |

Lower-cost Pd alternative, corrosion resistance equivalent to Gr. 7 |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, marine, offshore |

Ti-0.05Pd (Grade 17) |

Ti with 0.05% Pd |

Lower-cost Pd alternative, corrosion resistance equivalent to Gr. 11 |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, desalination, marine, medical |

Ti-0.1Ru (Grade 26) |

Ti with 0.1% Ru |

Corrosion resistance equivalent to Gr. 7 with Ru addition |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, marine, offshore, oil & gas |

Ti-0.1Ru (Grade 27) |

Ti with 0.1% Ru |

Corrosion resistance equivalent to Gr. 11 with Ru addition |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, marine, medical, oil & gas |

Alpha and Near-Alpha Alloys | ||||

Ti-0.3Mo-0.8Ni (Grade 12) |

Ti with 0.3% Mo, 0.8% Ni |

Improved strength, weldable, resistance to brine and reducing acids |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, marine, geothermal, offshore |

Ti-3Al-2.5V (Grade 9) |

Ti with 3% Al, 2.5% V |

Medium strength, high weldability, good cold formability |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Aerospace, marine, automotive, chemical processing |

Ti-3Al-2.5V-Pd (Grade 18) |

Ti with 3% Al, 2.5% V, Pd |

Pd-enhanced for resistance to brine and reducing acids |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, marine, geothermal, offshore |

Ti-3Al-2.5V-Ru (Grade 28) |

Ti with 3% Al, 2.5% V, Ru |

Ru-enhanced for brine resistance, approved for sour service |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Chemical processing, oil & gas, marine |

Ti-5Al-2.5Sn (Grade 6) |

Ti with 5% Al, 2.5% Sn |

Good high-temperature strength and creep resistance |

Ingot, Bar, Billet, Plate, Sheet |

Aerospace, gas turbines, chemical processing |

Alpha-Beta Alloys | ||||

Ti-6Al-4V (Grade 5) |

Ti with 6% Al, 4% V |

Heat-treatable, high strength, most widely used titanium alloy |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Aerospace, marine, automotive, chemical processing |

Ti-6Al-4V ELI (Grade 23) |

Ti with 6% Al, 4% V |

Extra low interstitial version, improved ductility and fracture toughness |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Medical implants, marine, aerospace |

Ti-6Al-4V-0.1Ru (Grade 29) |

Ti with 6% Al, 4% V, 0.1% Ru |

Improved fracture toughness, resistance to localized corrosion |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Oil & gas, marine, offshore, chemical processing |

Ti-6Al-6V-2Sn (Grade 6-6-2) |

Ti with 6% Al, 6% V, 2% Sn |

Higher strength than Ti-6Al-4V, lower toughness, good hardenability |

Ingot, Bar, Billet, Plate, Sheet |

Aerospace, high-strength components, military applications |

Ti-6Al-2Sn-4Zr-6Mo (Grade 6-2-4-6) |

Ti with 6% Al, 2% Sn, 4% Zr, 6% Mo |

Very high strength, deep hardenability, limited weldability |

Ingot, Bar, Billet, Plate, Sheet |

Aerospace, high-temperature components, gas turbines |

Ti-4Al-4Mo-2Sn-0.5Si (Grade 550) |

Ti with 4% Al, 4% Mo, 2% Sn, 0.5% Si |

Good strength and creep resistance, high-temperature stability |

Ingot, Bar, Billet, Plate, Sheet |

Aerospace, industrial high-temperature environments |

Near-Beta and Beta Alloys | ||||

Ti-10V-2Fe-3Al (Grade 10-2-3) |

Ti with 10% V, 2% Fe, 3% Al |

Heat-treatable, very high strength, excellent forgeability |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Aerospace, landing gear, high-strength, fatigue-resistant components |

Ti-3Al-8V-6Cr-4Zr-4Mo (Grade 19) |

Ti with 3% Al, 8% V, 6% Cr, 4% Zr, 4% Mo |

Very high strength, good toughness, low elastic modulus |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

High-temperature, corrosive environments, aerospace |

Ti-3Al-8V-6Cr-4Zr-4Mo-0.05Pd (Grade 20) |

Ti with 3% Al, 8% V, 6% Cr, 4% Zr, 4% Mo, 0.05% Pd |

Enhanced corrosion resistance, very high strength |

Ingot, Bar, Billet, Plate, Sheet, Tubing, Wire |

Oil & gas, marine, high-corrosion applications |

Ti-5Al-4Cr-4Mo-2Sn-2Zr (Grade 17) |

Ti with 5% Al, 4% Cr, 4% Mo, 2% Sn, 2% Zr |

High strength, deep section hardenability, creep resistance |

Ingot, Bar, Billet, Plate, Sheet |

Aerospace, gas turbines, high-temperature components |

In conclusion, titanium's exceptional properties, including its strength-to-weight ratio, corrosion resistance, and versatility, make it a highly sought-after metal across various industries. However, the vast array of titanium alloys and grades can be overwhelming. By understanding the classification of titanium alloys based on microstructure and strength characteristics, as well as the effects of alloying elements, you can make informed decisions for your specific applications.

From commercially pure titanium grades to alpha, alpha-beta, and beta alloys, each category offers unique properties and is suitable for different applications. Whether you require high strength, excellent corrosion resistance, or a combination of both, the titanium alloy landscape provides a diverse range of options. By carefully considering the specific requirements of your project, you can select the most appropriate titanium alloy to meet your needs and achieve optimal performance.

Reference

Veiga, C., Davim, J. P., & Loureiro, A. J. R. (2012). Properties and applications of titanium alloys: a brief review. Rev. Adv. Mater. Sci, 32(2), 133-148.

Welsch, G., Boyer, R., & Collings, E. W. (Eds.). (1993). Materials properties handbook: titanium alloys. ASM international.

Budinski, K. G. (1991). Tribological properties of titanium alloys. Wear, 151(2), 203-217.

https://www.spacematdb.com/spacemat/manudatasheets/TITANIUM%20ALLOY%20GUIDE.pdf