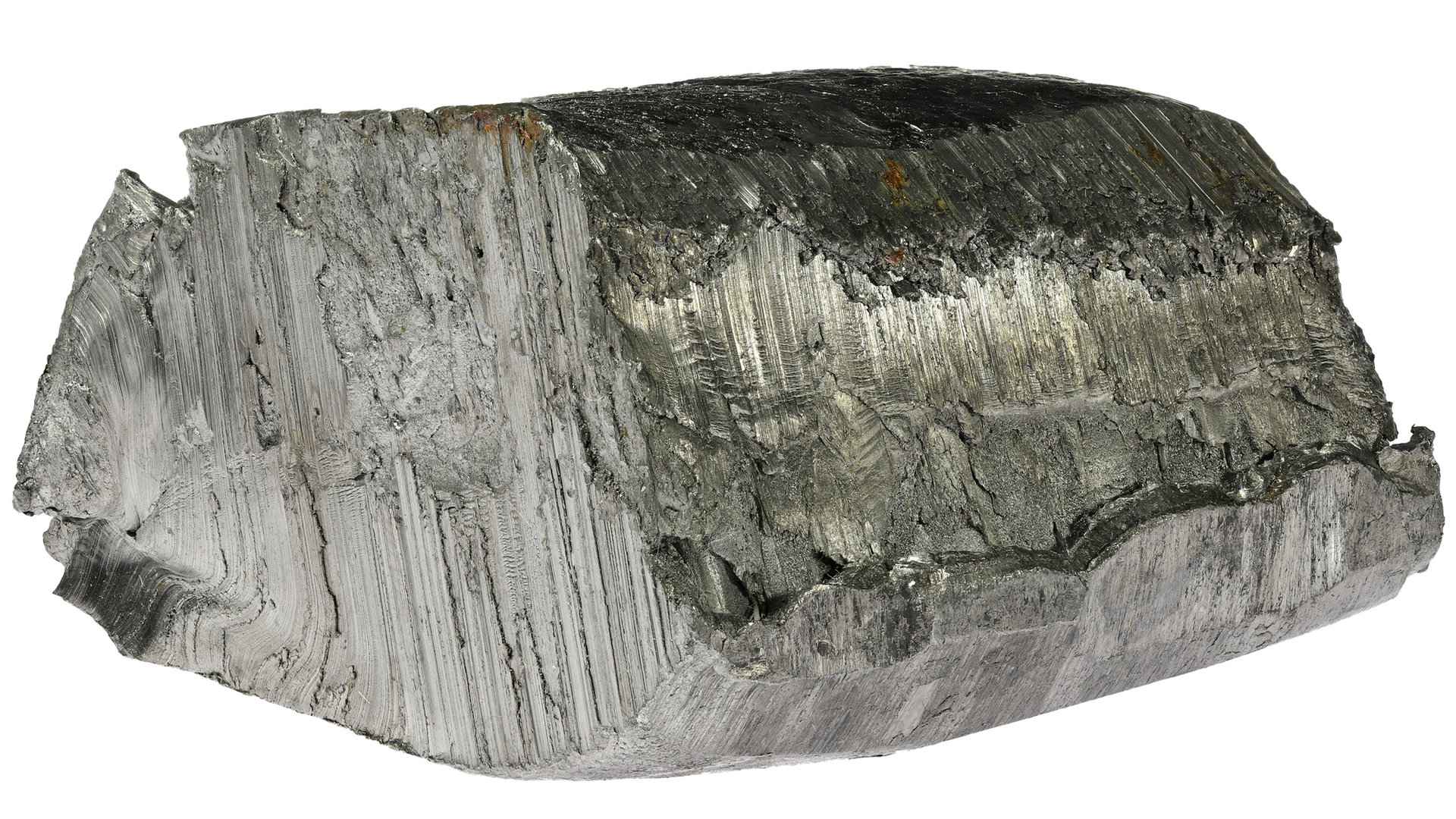

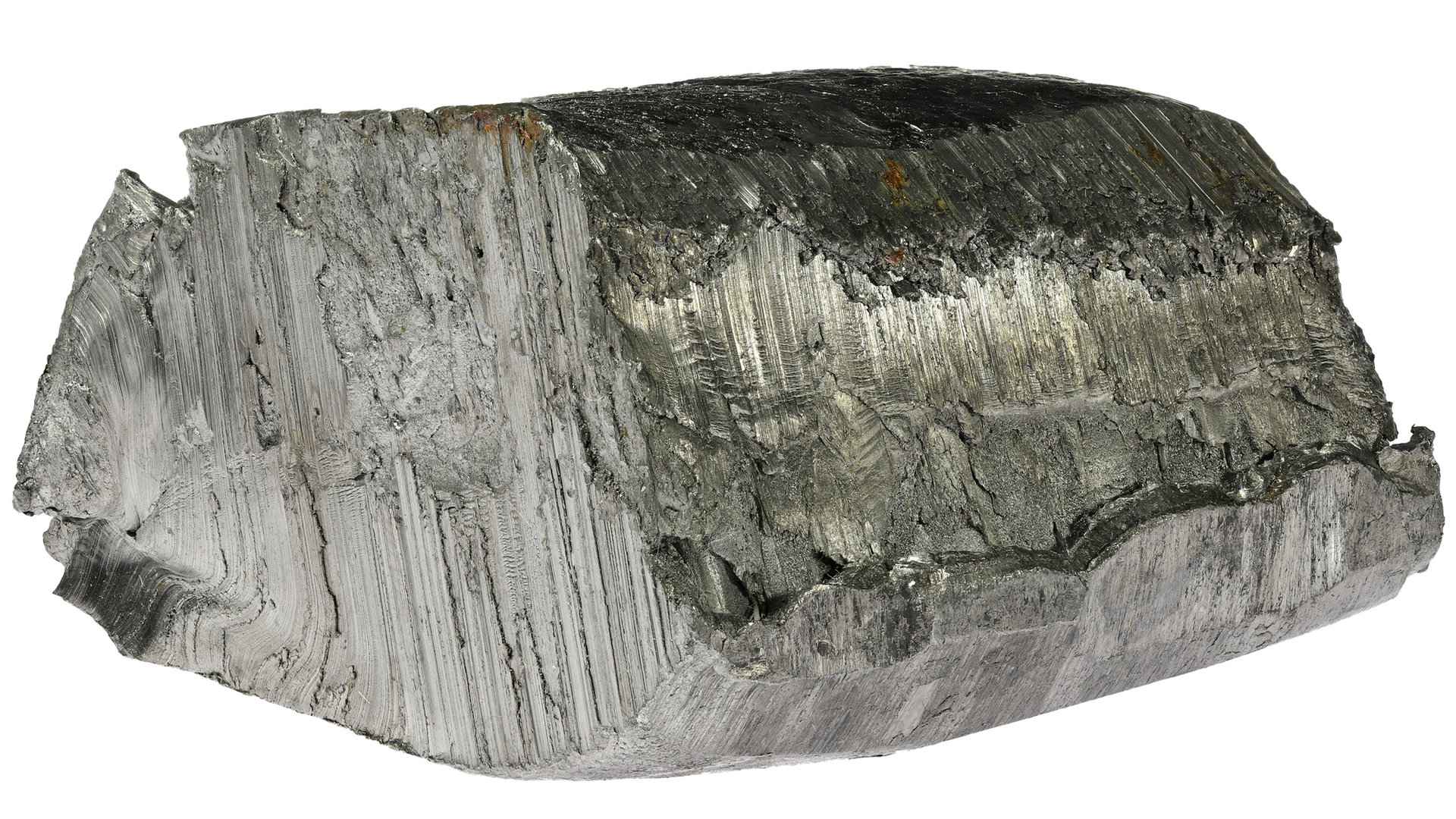

Niobium is a critical element in the manufacturing of High-Strength Low-Alloy (HSLA) steel, a material widely used in aviation, energy, and infrastructure industries. Its unique ability to enhance the strength, durability, and performance of steel has made it a valuable component in high-performance applications. However, an equally important question arises: How does the presence of niobium in HSLA steel affect its recyclability? As sustainability and cost-efficiency drive industries, understanding the recycling potential of niobium-containing materials becomes increasingly essential. In this article, we will explore how niobium impacts the recyclability of HSLA steel, its environmental and economic benefits, and why companies should prioritize the responsible recycling of niobium scrap.

HSLA steel is an advanced material known for its high strength and low weight, crucial for reducing material costs and enhancing energy efficiency in industries like aviation and energy. Niobium plays a pivotal role by refining the microstructure of steel, enabling superior mechanical properties such as tensile strength, impact resistance, and corrosion resistance. By adding small amounts of niobium (often less than 0.1% by weight), manufacturers can achieve substantial performance improvements in steel, making it ideal for demanding applications like jet engines, turbines, and pipeline infrastructure.

However, with the increased use of niobium comes the responsibility of managing the life cycle of these advanced materials. Recycling niobium-bearing steel is crucial for ensuring sustainability, reducing waste, and conserving raw material resources.

Niobium, despite being a high-performance alloying element, does not hinder the recyclability of HSLA steel. In fact, its presence can enhance the recycling process for several reasons:

One of the primary concerns with recycling alloys is whether the added elements degrade after multiple recycling cycles. Fortunately, niobium does not lose its beneficial properties when recycled, allowing HSLA steel to maintain its enhanced strength, durability, and corrosion resistance even after being reprocessed. This makes the recycling of niobium-containing scrap highly efficient.

HSLA steel containing niobium can be seamlessly integrated into existing steel recycling processes without significant modifications. This is because the alloying elements, such as niobium, titanium, and vanadium, are present in low quantities that do not interfere with the melting, refining, or alloying processes of recycled steel. Furthermore, niobium is chemically stable and does not volatilize or form problematic compounds during the steel recycling process.

Recycling niobium-containing HSLA steel is not only environmentally friendly but also economically advantageous. When recycled, niobium retains its high-strength properties, which allows manufacturers to produce strong, lightweight steel using less raw material. This reduces energy consumption and carbon emissions associated with mining and processing fresh niobium, a key advantage for industries looking to lower their environmental footprint.

Given the widespread use of HSLA steel in high-demand industries such as aviation and energy, there is a growing supply of niobium scrap available for recycling. Components like aircraft frames, turbines, pipelines, and automotive structures that have reached the end of their life cycle often contain niobium, offering a valuable source of recyclable material. As demand for high-strength steel continues to rise, the recycling of niobium scrap provides a critical resource for industries looking to meet performance and sustainability goals.

The aviation industry, which relies heavily on HSLA steel for aircraft structural components and engine parts, is a prime source of niobium-containing scrap. Recycling these materials offers significant benefits, including reduced manufacturing costs, lower energy consumption, and improved sustainability metrics. Aircraft manufacturers can recycle end-of-life components into new, high-strength parts without sacrificing performance, ensuring that niobium continues to deliver value throughout the material’s life cycle.

In the energy sector, HSLA steel is widely used in the construction of pipelines, oil rigs, and power generation infrastructure. Niobium strengthens these materials, enabling them to withstand high-pressure environments and corrosive conditions. As renewable energy initiatives increase and aging infrastructure is replaced, the demand for recycled materials is expected to rise. Recycling niobium-containing scrap can help meet this demand while reducing the need for new raw materials and minimizing environmental impact.

HSLA steel is also commonly used in construction due to its high strength-to-weight ratio, making it ideal for building bridges, skyscrapers, and other large-scale structures. As infrastructure projects evolve toward sustainable practices, the ability to recycle niobium-containing steel becomes an essential part of resource management. By recycling these materials, construction companies can reduce costs and contribute to the circular economy.

Companies in aviation, energy, and infrastructure industries should consider the following strategies to maximize the value of niobium scrap:

The recyclability of niobium-containing HSLA steel offers enormous potential for industries looking to reduce costs, improve performance, and enhance sustainability. The compatibility of niobium with existing recycling processes, combined with its ability to retain its material properties, makes it a valuable resource for future applications. As industries such as aviation and energy continue to prioritize sustainability, the recycling of niobium scrap will become increasingly important in meeting environmental and economic objectives.

If your company is looking to buy or recycle niobium scrap or niobium metals, Quest Metal offers industry-leading services in the recovery and recycling of high-performance alloys. Contact us today to explore how we can help you maximize the value of your niobium-containing materials.